M Series Robot Cameras : – In today’s rapidly evolving world of industrial automation, vision systems play a critical role in improving accuracy, speed, and adaptability. Among the most advanced technologies in this space are M Series robot cameras—a cutting-edge solution engineered to provide high-resolution, real-time imaging capabilities for robotic systems across various industries.

This in-depth guide will explore everything you need to know about M Series robot cameras, including how they work, their benefits, top use cases, technical specifications, and how they compare to other vision solutions on the market.

Whether you’re an engineer, a robotics integrator, or a decision-maker exploring automation upgrades, this article will help you understand why M Series robot camera are transforming the way robots see and interact with the world.

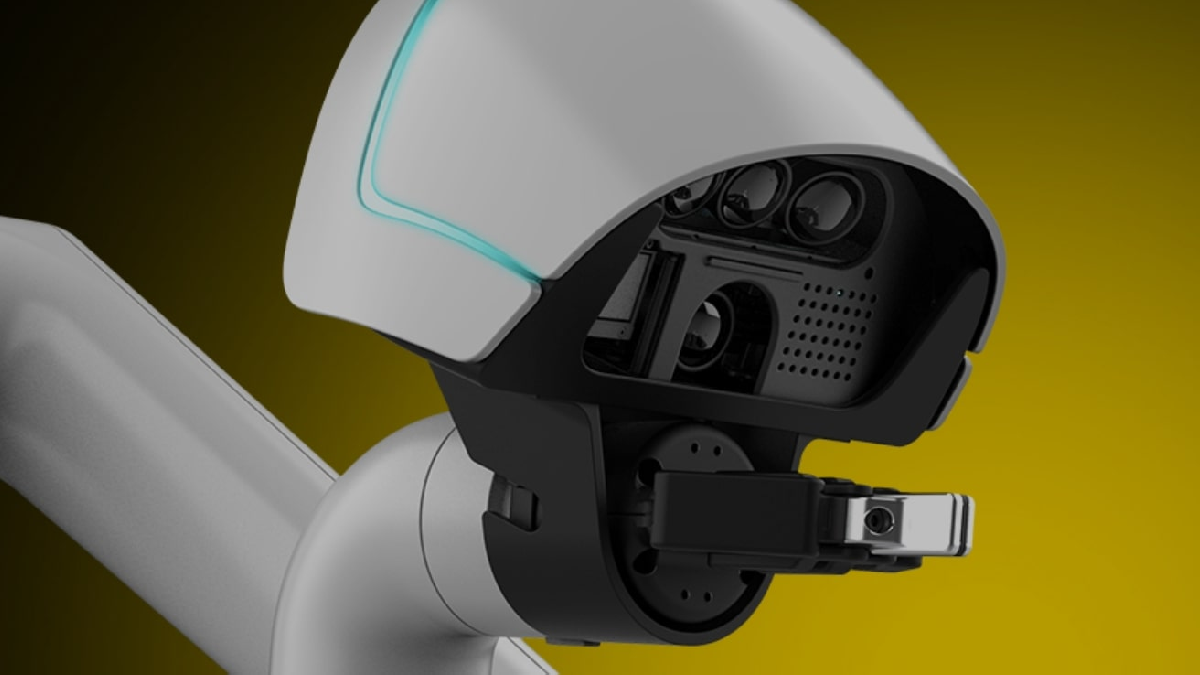

What Are M Series Robot Cameras?

M Series robot cameras are high-performance machine vision cameras specifically designed for robotic applications. They typically feature advanced imaging sensors, robust housings, fast frame rates, and plug-and-play integration with industrial robots. These cameras provide robots with the ability to perceive and interpret their surroundings in fine detail, enabling tasks like object detection, inspection, quality control, and autonomous navigation.

Unlike traditional cameras, M Series robot camera are built to handle the harsh demands of industrial environments, such as vibration, variable lighting, and complex 3D structures.

Key Features of M Series Robot Cameras

M Series robot cameras come equipped with several features that set them apart from conventional machine vision cameras:

- High-resolution image sensors (ranging from 2MP to over 20MP)

- Compact and rugged design for integration with robotic arms or mobile platforms

- Fast image processing with on-board computation or external GPU/CPU compatibility

- Flexible lens options including fixed focus, zoom, and telecentric lenses

- Real-time 3D imaging with depth perception for spatial awareness

- Compatibility with AI algorithms for defect detection, sorting, and object classification

- Standard communication protocols such as GigE, USB 3.0, and PoE

These capabilities make M Series robot cameras ideal for high-precision applications where speed, accuracy, and durability are paramount.

Top Applications of M Series Robot Cameras

M Series robot cameras are being deployed across various industries to improve automation and operational efficiency. Here are some of the most common use cases:

1. Automated Inspection and Quality Control

Manufacturers use M Series robot cameras to perform non-contact visual inspections on production lines. The cameras detect surface defects, misalignments, scratches, or inconsistencies in real time. This reduces the risk of defective products reaching the customer and minimizes costly recalls.

2. Robotic Pick-and-Place

In logistics, warehousing, and packaging, M Series robot cameras guide robotic arms to accurately locate, pick, and place items of varying shapes and sizes. These systems are often powered by 3D vision and AI to adapt to dynamic environments.

3. Precision Assembly

When it comes to assembling electronic components or miniature parts, accuracy is key. M Series robot cameras help robots align components with sub-millimeter precision, ensuring consistent and high-quality assembly.

4. Autonomous Mobile Robots (AMRs)

M Series robot cameras enable AMRs to navigate warehouse environments, detect obstacles, and make routing decisions in real time. The depth and 3D sensing capabilities of these cameras are essential for spatial awareness and safety.

5. Machine Tending

In CNC machining, injection molding, or metalworking, M Series robot cameras allow robots to load and unload materials automatically. Vision-based validation ensures only correctly shaped and positioned parts are processed.

Benefits of Using M Series Robot Cameras

The adoption of M Series robot cameras brings several strategic benefits to organizations seeking to optimize their automation systems:

Enhanced Accuracy

With ultra-high resolution and advanced optics, M Series robot cameras deliver precise and consistent visual feedback, which translates into better quality control and more reliable automation.

Faster Throughput

By enabling robots to make real-time decisions based on visual input, these cameras contribute to higher production speeds without sacrificing quality.

Reduced Downtime

M Series robot cameras are designed for durability and minimal maintenance. Their ability to detect and adapt to anomalies reduces errors and operational disruptions.

Flexibility and Scalability

As business needs change, M Series robot cameras can be easily reconfigured for different tasks, making them suitable for flexible manufacturing environments.

Lower Operational Costs

Although the initial investment in vision-based robotics may seem high, M Series robot cameras help cut long-term labor and inspection costs, resulting in a high return on investment.

Technical Specifications of M Series Robot Cameras

While specifications may vary between models and manufacturers, here’s a general overview of what to expect from a high-end M Series robot camera:

| Feature | Specification |

| Sensor Type | CMOS (Global or Rolling Shutter) |

| Resolution | 2MP to 24MP |

| Frame Rate | Up to 120 fps (model-dependent) |

| Interface | GigE Vision, USB 3.0, PoE, Camera Link |

| Lens Mount | C-Mount, CS-Mount, F-Mount |

| Image Formats | RAW, JPEG, BMP, PNG |

| Operating Temperature | -10°C to 60°C |

| Housing | IP65/IP67 rated for industrial environments |

| Software Integration | Compatible with OpenCV, HALCON, MATLAB, ROS |

| AI Integration | Supports TensorFlow, PyTorch, ONNX models |

How M Series Robot Cameras Compare to Other Vision Systems

When evaluating vision systems, it’s essential to understand how M Series robot cameras stack up against alternative technologies.

| Feature | M Series Robot Cameras | Traditional Vision Cameras | ToF Sensors |

| Image Quality | High-resolution | Medium to high | Low to medium |

| Depth Sensing | Advanced (3D vision) | Limited | Yes (but lower detail) |

| Speed | Very fast | Moderate to fast | Fast |

| Durability | Industrial-grade | Varies | Good |

| Cost | Moderate to high | Low to moderate | Moderate |

| AI and ML Compatibility | Excellent | Limited | Limited |

M Series robot cameras strike an excellent balance between image quality, speed, depth sensing, and integration capabilities—making them ideal for next-generation automation.

Choosing the Right M Series Robot Camera for Your Needs

When selecting a camera from the M Series, consider the following criteria to ensure it meets your application requirements:

- Field of view: Match the camera’s lens and resolution to the size of the objects you’re inspecting.

- Lighting conditions: Choose models with good low-light performance or built-in illumination for consistency.

- Processing needs: Determine whether you need onboard processing or integration with external AI systems.

- Communication protocol: Verify compatibility with your existing robot controller or PLC.

- Environment: Ensure the housing and temperature range suit your working conditions.

Consulting with a robotics vision expert or camera vendor can help match your application to the ideal model in the M Series.

Future Trends in M Series Robot Cameras

As robotics and AI continue to evolve, so will M Series robot cameras. Here are some exciting developments on the horizon:

- Edge AI Processing: Cameras will increasingly process images locally using edge AI chips, reducing latency.

- Multi-sensor Fusion: Future models may combine visual, thermal, and LiDAR data for a richer understanding of environments.

- 5G Connectivity: Ultra-fast data transmission will allow real-time camera control and cloud processing.

- Augmented Reality Integration: Enhanced vision systems will support AR overlays for diagnostics and training.

- Self-calibration and Auto-tuning: Cameras will become more autonomous, adjusting settings in real time for optimal performance.

Final Thoughts

M Series robot cameras are revolutionizing machine vision by empowering robots with the eyes—and the intelligence—they need to perform complex tasks with precision and speed. From quality control and robotic guidance to 3D object recognition and autonomous navigation, these cameras are unlocking new levels of automation across industries.

If you’re planning to upgrade your factory floor, warehouse, or robotic workflow, investing in M Series robot cameras is a smart step toward higher productivity, lower error rates, and a more agile operation. With the right integration and support, these powerful vision systems will give your robots the visual advantage they need to compete in the smart factories of tomorrow.